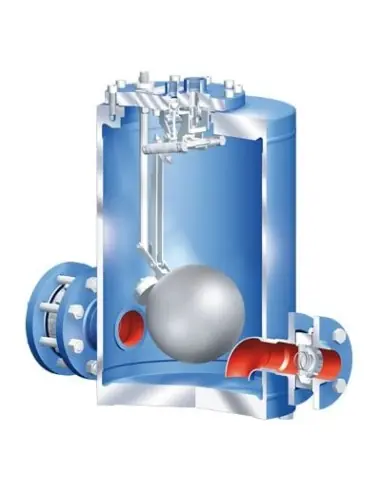

ARI-CONLIFT® Condensate Pump Features:

- Operation: No electricity required, operates automatically by adapting to the condensate level.

- Design: Robust and durable, made from high-quality materials such as stainless steel, high-temperature steel, and SG iron.

- Internal Components: Made from stainless steel, with wear parts made from hardened stainless steel for longevity. Inconel X-750 springs are used for high endurance.

- No Leakage: Due to the absence of moving exterior parts, the pump does not leak.

- Low Filling Head: The pump is designed to work effectively even with a low filling head.

- Applications: Suitable for pumping condensate from low-level systems to higher pressure or higher-level systems.

Construction Materials:

- Body: Varies by model, options include P235GH-TC, P250GH, P265GH, 1.4571 stainless steel, and EN-GJS-400-18-LT.

- Cover: P265GH or stainless steel 1.4571.

- Other Components: A4-70 stainless steel studs and other components made of high-quality alloys.

Operating Limits:

- Pressure:

- Maximum operating pressure 10 bar (some models).

- Back pressure can vary, but typical limits are between -1.0 barg and 10 barg.

- Temperature:

- Operating temperature range of -10°C to 200°C for most models.

Sizes and Capacities:

- The pump models are available in various sizes with nominal diameters like DN25, DN40, DN50, and DN80.

- Displacement ranges from 16.5 to 20 liters.

Flow Rate:

- The flow rate depends on the back pressure and the motive medium (steam, compressed air, or inert gas).

- Different sizes and configurations allow for adjustable flow rates, ranging from 16.5 liters to 20 liters per operation cycle.

Installation:

- The pump can be installed in a horizontal position and is ideal for applications that require automatic operation without external power sources.

- Filling head: The required filling head above the pump's footprint is typically 600 mm, with an option for 640 mm using an L-section stand.

Sizing and Installation Considerations:

- Sizing is based on flow capacity, motive medium, motive medium pressure, filling head, and back pressure.

- Correct sizing ensures optimal pump operation, avoiding excessive energy consumption or wear.

Correction Factor:

- If compressed air or inert gas is used as the motive medium, the flow rates need to be adjusted by a correction factor, depending on the back pressure.