Ball Float and Thermostatic

Ball Float and Thermostatic

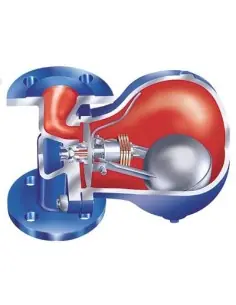

Ball float steam traps are essential components in many industrial steam systems. They help remove unwanted water, known as condensate, to keep steam systems working efficiently and safely. When steam is used for heating or power, it cools down and turns back into water. If this water isn't removed quickly, it can cause problems like water hammer, corrosion, or reduced efficiency. That's where ball float steam traps come in.

These reliable devices use a simple yet effective mechanism. Inside the trap, a floating ball rises and falls with the level of water. As more water enters, the ball lifts and opens a valve, allowing the water to drain away automatically. When the water level drops, the ball falls, closing the valve and keeping steam from escaping. This means your equipment runs smoothly, without wasting energy or steam.

Ball float steam traps work well even at low pressure differences, making them suitable for many applications, from heating systems to process equipment in factories. They handle sudden changes in flow smoothly and discharge condensate continuously, which means steam equipment can perform at its best all the time.

With their sturdy construction and reliable operation, ball float steam traps are a smart choice for anyone looking to maintain efficient, trouble-free industrial steam systems. Investing in quality steam traps helps save energy, protect your equipment, and ensure a safer workplace.

Ball Float and Thermostatic

Float & thermostatic steam trap - CONA S | ARI

Ball Float and Thermostatic

Float operated pump trap - CONA P | ARI

Ball Float and Thermostatic