Back Pressure Regulator - UV 4.5 | Mankenberg: Power and Precision for Industrial Flow Control

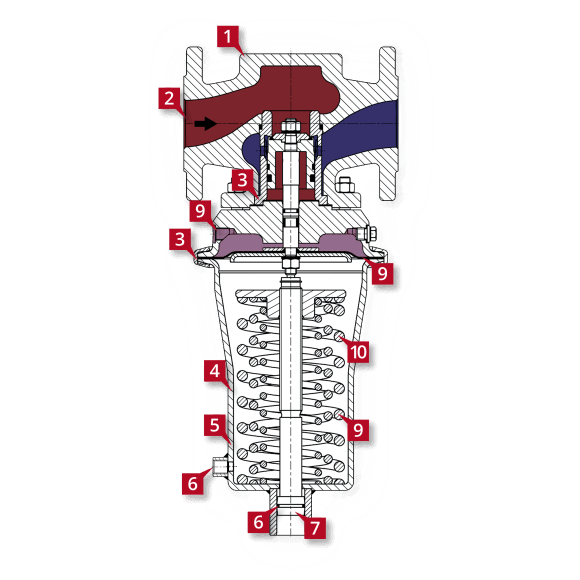

The Back Pressure Regulator - UV 4.5 | Mankenberg brings unrivaled control and reliability to your industrial processes. Designed for demanding applications, this high-performance regulator keeps your system running smoothly by managing pressure with total confidence. Whether you’re dealing with liquids, gases, or steam, it maintains optimal conditions so your operations are efficient and safe.

Features and Benefits of the Back Pressure Regulator - UV 4.5 | Mankenberg

-

Stable Pressure Control:

Ensures your system stays within set pressure limits, protecting equipment and reducing the risk of costly downtime. -

Automatic Adjustment:

Reacts instantly to pressure changes, keeping everything running at the right balance without constant manual checks. -

Durable Construction:

Built with high-quality stainless steel and robust materials, offering excellent resistance to wear, corrosion, and harsh environments. -

Easy to Install:

Compact and lightweight design makes installation straightforward, saving time and effort. -

Low Maintenance:

Minimal moving parts help keep maintenance needs low and extend the lifespan of the regulator. -

Versatile Use:

Perfect for a wide range of industrial sectors including chemical processing, water treatment, and power generation.

The UV 4.5 makes advanced pressure management accessible to everyone. No need for technical expertise – just set your desired pressure, and it does the rest. Its precision ensures that critical processes run without interruption and with maximum safety.

For industries where reliability and safety come first, the Back Pressure Regulator - UV 4.5 | Mankenberg is an essential addition. Achieve peace of mind and operational stability, knowing your system is protected and optimized every step of the way.