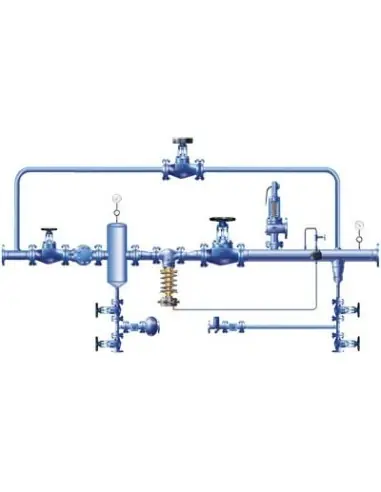

ARI-PREsys® Overview:

- Pressure Reducing Stations (PRS) are self-acting or equipped with electro-pneumatic control.

- Available models:

- ARI-PREsys®-S (for steam)

- ARI-PREsys®-W (for water)

- ARI-PREsys®-A (for air)

Key Features:

- Compact design: Easy installation with clear setup instructions.

- Maintenance-free design using stainless steel bellows.

- Process security: Utilizes harmonized components to ensure stable operation.

- Pressure-secure subassembly: Built to guarantee safety.

- Dry and clean process steam: Optionally includes a steam drier.

- Bypass pipe for emergency operation: Ensures continued function even during maintenance.

- Condensate drain option on the minimum pressure side.

- Wall or floor brackets for installation.

Pressure Reducing Station Models:

- PRS-S: Basic design for steam, self-acting.

- PRS-S Plus: Includes condensate drain on the P2 side.

- PRS-S Complete: Comes with complete equipment, including a steam drier, bypass, and full condensate drains.

- PRS-W and PRS-A: Models designed for water and air, respectively, also available in complete versions.

Pressure-Temperature Ratings:

- The pressure-temperature chart provides operational limits, which depend on the materials used and temperature.

- For example:

- EN-JL1040 (Cast Iron) operates at 16 bar max at 50°C, dropping to 9.6 bar at 350°C.

- 1.0619+N (Carbon Steel) operates at 40 bar max at 50°C, dropping to 24 bar at 350°C.

Applications:

- The pressure reducing stations are primarily used to reduce a higher input pressure to a lower, safe output pressure.

- The system is ideal for industrial steam, air, and water systems, providing stable pressure reduction without the need for auxiliary power.

Technical Data:

- The pressure reducing valves come in multiple sizes with Kvs values ranging from 3.2 m³/h for small sizes (DN15) to 125 m³/h for larger sizes (DN100).

- The stations can be designed with various control methods, including self-acting control or electro-pneumatic control for more precision.

System Design Options:

- The system offers customizable designs with options such as bypass pipes, condensate drains, and specific valve materials based on the application (e.g., EN-JL1040, EN-JS1049, 1.4408 for stainless steel components).