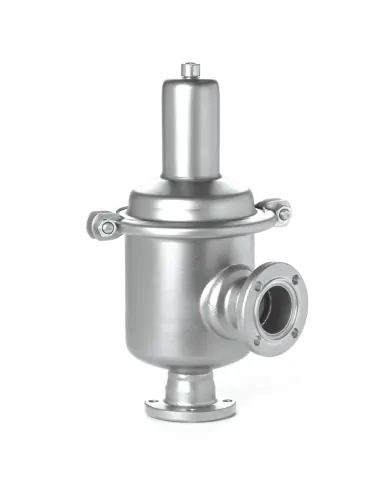

Pressure reducing valve Type DM 462 | Mankenberg – Reliable Pressure Control for Every Industrial Setting

Experience unmatched stability and efficiency in your industrial operations with the Pressure reducing valve Type DM 462 | Mankenberg. This innovative valve is engineered to maintain a consistent downstream pressure, ensuring safety and smooth performance even under fluctuating inlet pressures. It’s the perfect solution for industries demanding precision and reliability in pressure management.

Features & Benefits of the Pressure reducing valve Type DM 462 | Mankenberg

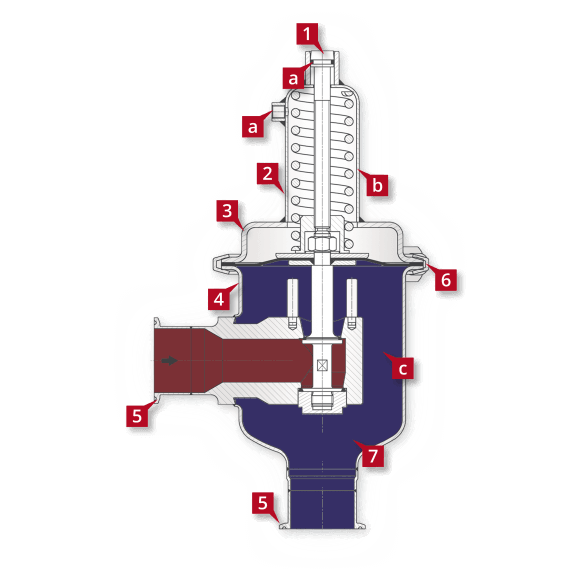

- Consistent Pressure Control: The DM 462 ensures optimal pressure regulation, protecting sensitive equipment and pipelines from pressure surges.

- Durable Construction: Made with high-quality materials, this valve is built to withstand the toughest industrial environments, guaranteeing long-term use and minimal maintenance.

- Effortless Installation: Designed for easy integration into existing systems, the DM 462 saves time and reduces overall installation costs.

- Low Maintenance: Thanks to its robust design, routine maintenance is kept to a minimum, reducing downtime and operational costs.

- Precise Adjustment: Fine-tune the output pressure to your exact needs with user-friendly adjustment options, making the valve suitable for a wide range of applications.

- Versatile Applications: Whether you’re working with water, steam, or gases, the DM 462 delivers consistent results, making it an all-rounder in various industrial sectors.

The Pressure reducing valve Type DM 462 | Mankenberg is ideal for anyone who wants safe and stable pressure without worrying about complicated setups. Its advanced features work quietly in the background, giving you peace of mind and confidence in your system’s performance. If you value reliability, easy operation, and long-lasting quality, this valve is the smart choice to keep your operations running smoothly.