Pressure Reducing Valve Type DM 462V | Mankenberg: Precision for Industry

Experience reliable pressure control with the Pressure Reducing Valve Type DM 462V from Mankenberg, expertly designed for industrial needs. This robust valve ensures your systems always operate at the optimal pressure, boosting safety and efficiency in every application. Whether you're managing water, steam, or gases, this valve is a dependable choice that safeguards your equipment and processes.

Features & Benefits of the Pressure Reducing Valve Type DM 462V | Mankenberg

- Automatic Pressure Control: Ensures a consistent downstream pressure, no matter the fluctuations in supply. Ideal for processes that rely on steady performance.

- Stainless Steel Construction: High-grade materials provide lasting durability and resistance to corrosion, perfect for harsh industrial environments.

- Low Maintenance: The proven self-acting mechanism reduces the need for regular checks, saving you time and lowering operating costs.

- Wide Application Range: Suitable for liquids, gases, and steam, offering unmatched versatility in a variety of industries.

- Easy Installation: The compact design fits seamlessly into new or existing pipelines with minimal effort, reducing downtime during upgrades or repairs.

- Accurate Pressure Adjustments: Fine-tune your system with simple adjustments to ensure your process remains safe and efficient.

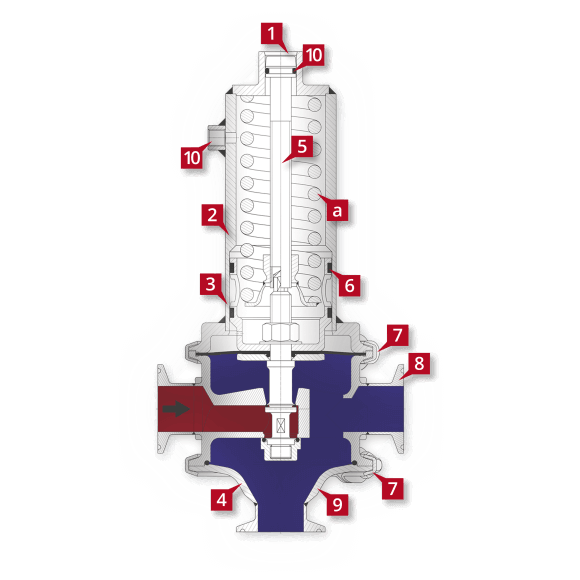

The Pressure Reducing Valve Type DM 462V is engineered for trouble-free operation in demanding settings. Its advanced diaphragm technology automatically balances incoming pressure, so you can trust it to deliver stable results, even when your supply is unpredictable. This means less worry about damaging sensitive equipment or disrupting production lines.

With its rugged stainless steel body, the DM 462V stands up to corrosive media and high temperatures, maintaining its performance year after year. Maintenance is straightforward, and its efficient design minimizes wear, helping to prevent unexpected breakdowns.

From manufacturing plants to chemical processing, the Pressure Reducing Valve Type DM 462V | Mankenberg adapts effortlessly to your industrial needs. Choose this valve for reliable pressure control, robust construction, and the peace of mind that comes with Mankenberg quality.