Superior Control and Efficiency: Pressure reducing Valve - Pilot Operated for steam - RE3 | Miyawaki

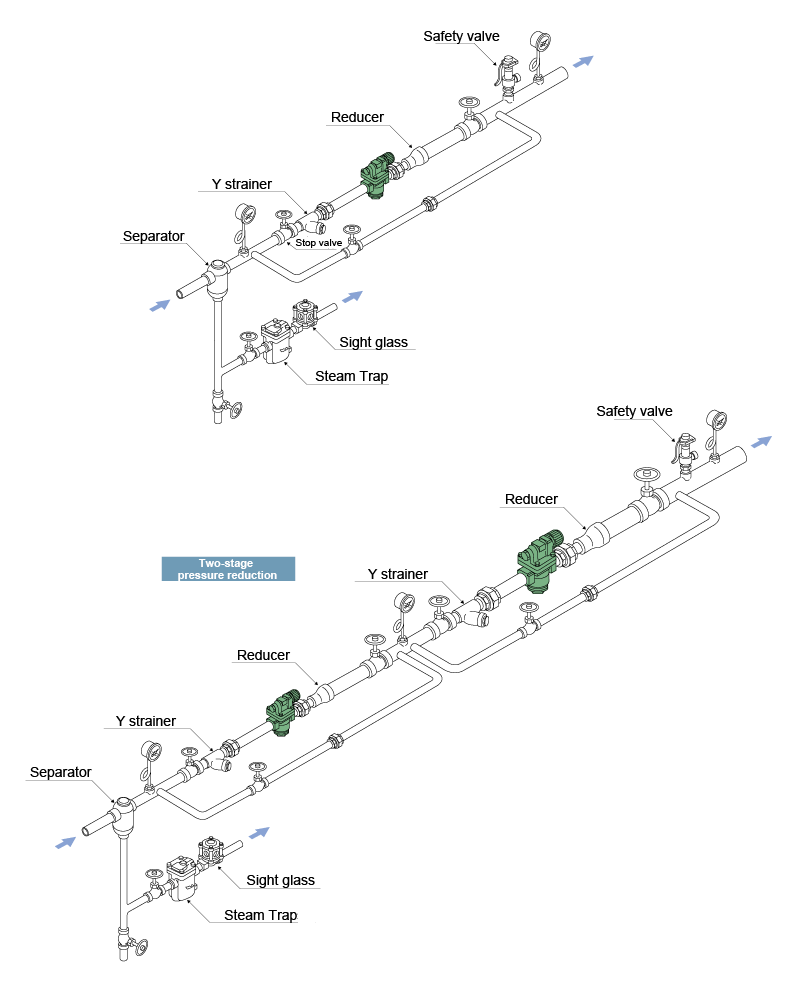

The Pressure reducing Valve - Pilot Operated for steam - RE3 | Miyawaki brings reliability and efficiency to industrial steam systems. Engineered for consistent performance, this valve ensures stable pressure, extends equipment life, and increases operational safety. Perfect for demanding industrial environments, it is your go-to solution for precise steam regulation.

Key Features & Benefits of Pressure reducing Valve - Pilot Operated for steam - RE3 | Miyawaki

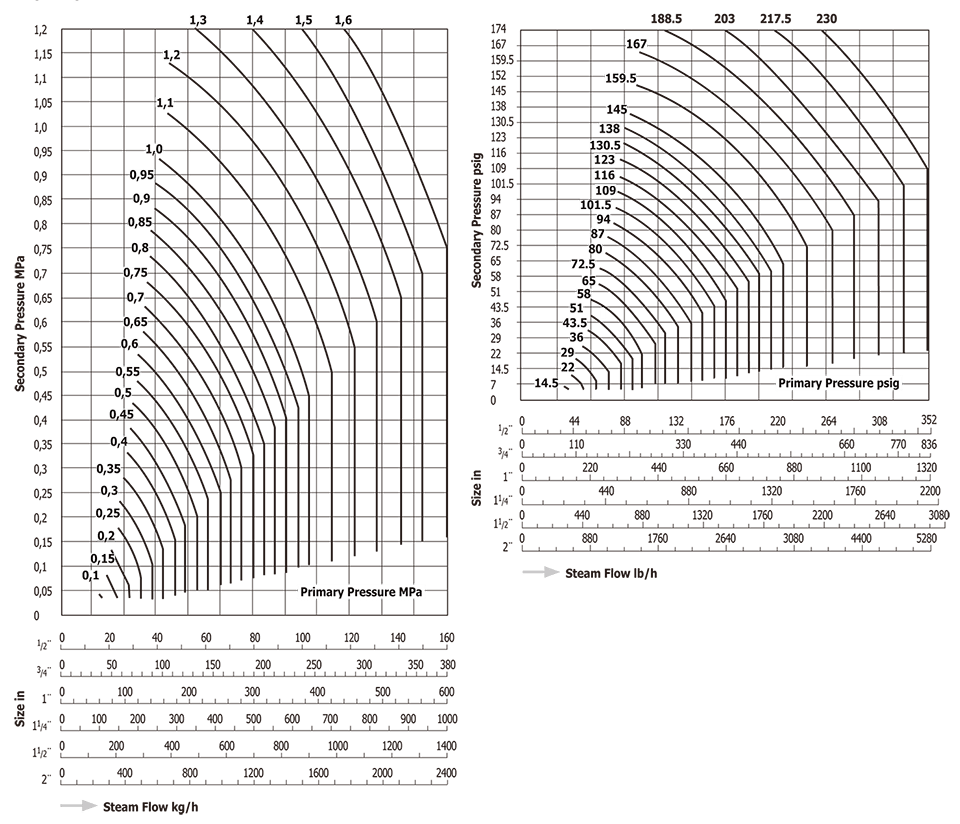

- Accurate Pressure Control: Maintains steady downstream pressure regardless of upstream fluctuations, delivering peace of mind and smooth operation.

- Pilot-Operated Precision: The pilot-operated design allows for faster and more sensitive pressure adjustments, giving you energy savings and optimal system performance.

- Durable Construction: Crafted with robust materials, it withstands demanding industrial conditions, reducing maintenance needs and downtime.

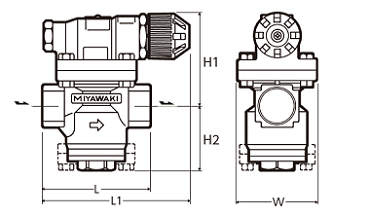

- Easy Integration: Fits seamlessly into existing steam networks, making installation simple and straightforward for maintenance teams.

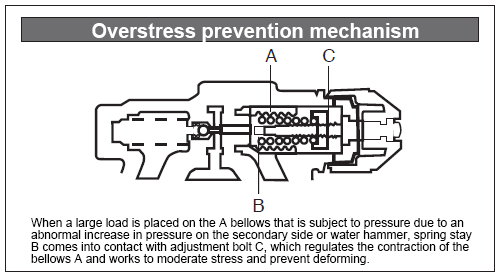

- Enhanced Safety: By controlling overpressure, it helps protect connected devices and piping from costly damage.

- Efficient Energy Use: Helps prevent waste by maintaining only the pressure you need, lowering energy consumption and operating costs.

- Low Noise Operation: Designed to minimize noise levels during operation, contributing to a safer and more comfortable working environment.

With the Pressure reducing Valve - Pilot Operated for steam - RE3 | Miyawaki, you gain advanced technology that simplifies steam management. The valve’s smart pilot system quickly senses and reacts to pressure changes, ensuring secure and uninterrupted steam delivery to your equipment. Its rugged body resists corrosion and wear, even in high-temperature and high-pressure settings.

Ideal for factories, processing plants, and any facility using steam, this valve protects sensitive machinery, cuts down on repair bills, and boosts overall productivity. Trust in the proven performance and quality engineering of Miyawaki to keep your steam systems running smoothly, safely, and efficiently.