Reliable Performance and Control: Pressure reducing Valve - Pilot Operated for steam - RE10N | Miyawaki

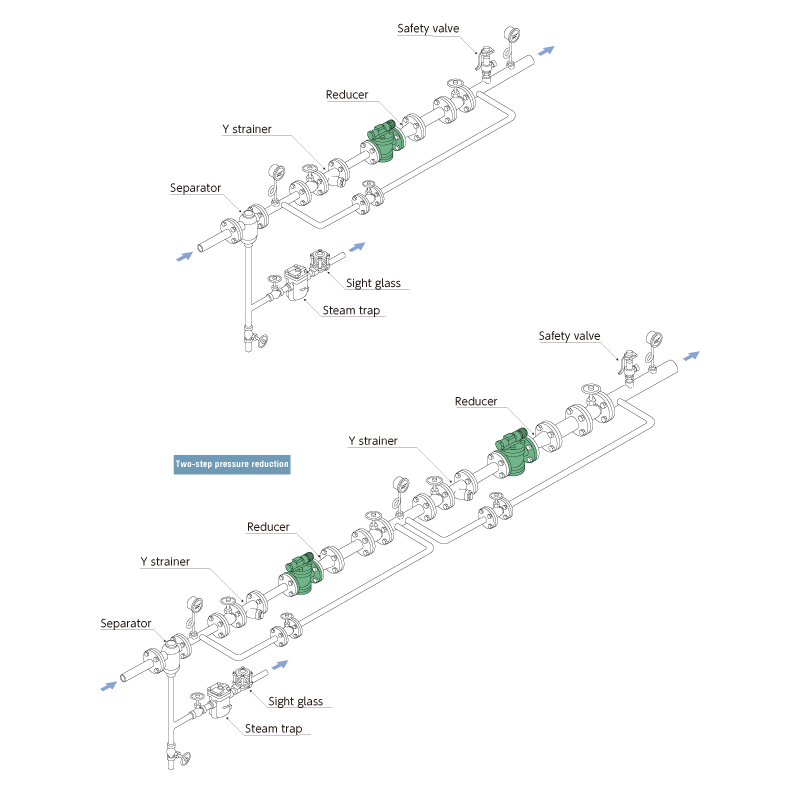

The Pressure reducing Valve - Pilot Operated for steam - RE10N | Miyawaki is expertly engineered to deliver superior steam management in industrial environments. This advanced valve guarantees stable pressure control, ensuring both safety and efficiency across your operations. Designed for reliability and easy integration, it is the ideal solution for industrial processes demanding consistent and precise steam flow.

Features and Benefits of Pressure reducing Valve - Pilot Operated for steam - RE10N | Miyawaki

-

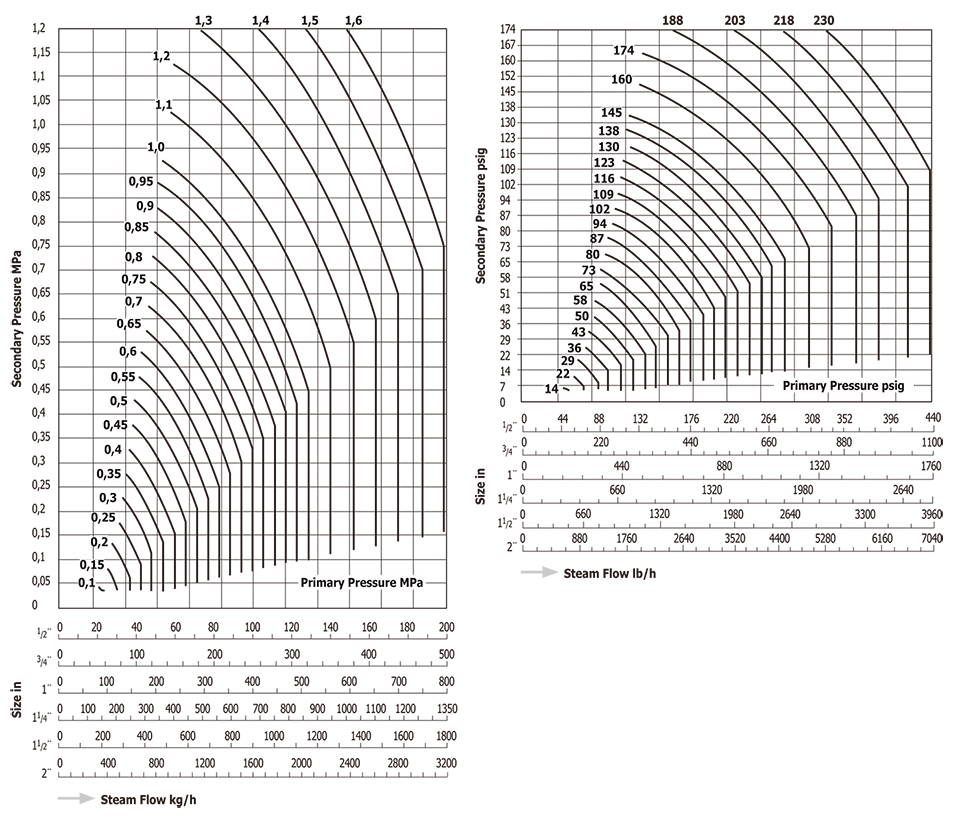

Consistent Pressure Control:

The pilot-operated technology ensures steady and accurate steam pressure, reducing fluctuations and preventing equipment stress. -

Energy Efficiency:

By maintaining optimal pressure, the valve helps cut unnecessary energy consumption, lowering your operational costs significantly. -

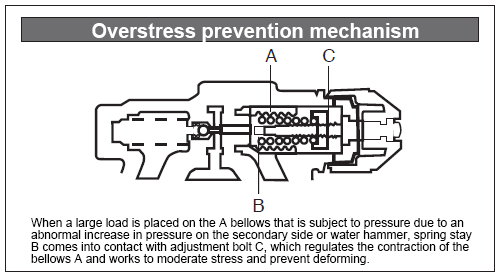

Enhanced Safety:

Built with robust safety mechanisms, it reduces the risk of steam surges, protecting your expensive machinery and safeguarding your workplace. -

Durable Construction:

Made from high-quality materials, the RE10N valve withstands the toughest industrial conditions, offering lasting durability and performance. -

Low Maintenance:

With its smart design, the valve is simple to install and requires minimal maintenance, minimizing downtime and saving you on repair costs. -

Precision Pilot Operation:

The separate pilot chamber delivers swift responses to pressure changes, guaranteeing smooth operations and reliable performance.

The Pressure reducing Valve - Pilot Operated for steam - RE10N | Miyawaki stands out for its user-friendly operation and outstanding dependability. Its pilot-operated action means adjustments are effortless and require no technical expertise. The versatile design makes it suitable for a wide range of industrial steam systems, from small-scale factories to large production plants.

With the RE10N, you have the confidence that your steam applications will run efficiently and safely. This valve not only meets today’s industrial standards but exceeds expectations when it comes to reliability and practicality.

Upgrade your steam management system and experience trouble-free, efficient, and reliable process control with the Pressure reducing Valve - Pilot Operated for steam - RE10N | Miyawaki.