Pressure reducing valve - Direct Acting for steam - REC1 | Miyawaki: Ultimate Steam Control for Industrial Efficiency

Enhance your steam system with the Pressure reducing valve - Direct Acting for steam - REC1 | Miyawaki, designed to deliver unmatched performance in industrial settings. This advanced valve ensures your steam pressure is always at optimal levels, protecting both your equipment and processes while maximizing energy efficiency.

Key Features & Benefits: Pressure reducing valve - Direct Acting for steam - REC1 | Miyawaki

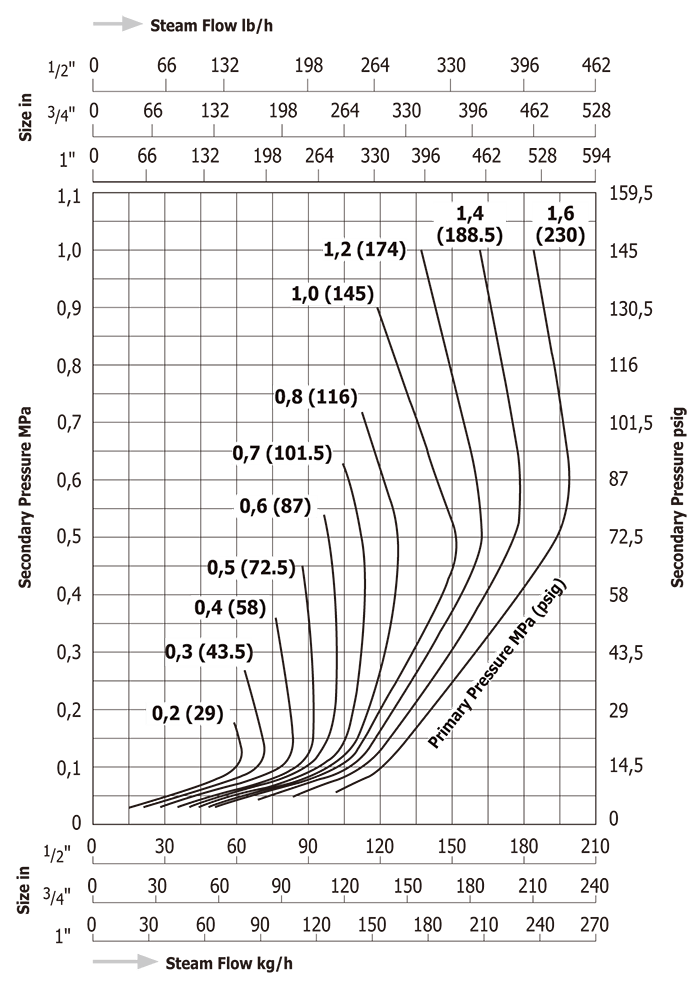

- Consistent Pressure Control: The REC1’s direct acting technology maintains steady steam pressure, preventing sudden fluctuations and keeping your operations running smoothly.

- Energy Savings: By delivering only the pressure you need, this valve reduces energy waste, helping you save on operational costs and increasing overall efficiency.

- Reliable Safety: The precise pressure regulation guards your equipment against excess pressure, minimizing maintenance risks and costly downtimes.

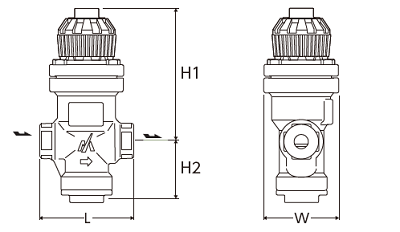

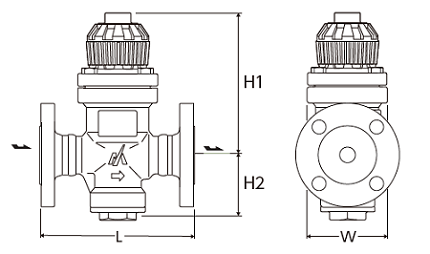

- Simple Installation: Compact and robust, the REC1 is easy to fit into existing steam lines with minimal disruption, making upgrades straightforward.

- Durable Construction: Built from high-quality materials, this valve withstands tough industrial environments, ensuring long-lasting performance and reliability.

The Pressure reducing valve - Direct Acting for steam - REC1 | Miyawaki is engineered for straightforward operation. There’s no need for complicated adjustments or technical skills. Once installed, it starts working immediately, automatically lowering steam pressure to the perfect level for your application. This means less stress on your system, improved process consistency, and reduced risk of equipment failure.

Thanks to its direct acting design, the REC1 responds instantly to changes in pressure. Whether your steam demand goes up or down, this valve adapts in real time, keeping your system stable and your operations safe. It’s an ideal solution for factories, plants, and any industrial site needing dependable steam control.

Choose the Pressure reducing valve - Direct Acting for steam - REC1 | Miyawaki for smart pressure management, lower running costs, and peace of mind for your steam applications.