DESIGN FEATURES

The nozzle check valves characterise for an effective dynamic response under various flow deceleration conditions.

Generally compared to other traditional check valves, the valve design is superior in performance, lower pressure drop ( depending size and form) and response.

The axial movement of the disc is giving a streamlined flow path obtaining the Venture effect.

Generally spoken the axial graded nozzle formed check valves have presently a much better dynamic performance compared to other conventional.

Its application on high pressure pumping equipment is not only allowing a better dynamic performance but also a more durable design compared well other conventional check valves.

As the flow is streaming smoothly through the valves it is not exposed to continuous movements.

APPLICATIONS

Pumping stations

Water transmissions

Water treatment

Desalination plants

TECHNICAL DATA

RANGE: DN 100 to DN 900

Design: EN16767(EN12516-1) / API594 (ASME B16.34)

Connections: Flanged PN10 to PN100 ACC. to EN1092-1 / ISO7005-1 / BS 4504 sect. 3.2 ANSI125#/600# ACC. to ASME B16.1/B16.5.

Face to Face: API594 (300#-600#) others no standard.

Operating temperatures: -20ºC +200ºC (rubber seated) others inquire.

Testing: EN12266 (ISO5208) / API598. Minimum pressure for tightness: 0.2 bar.

Materials: Ductile Iron, Steel, Stainless steel, superduplex, brz -alu.

TECHNICAL PERFORMANCE

Reduces water hammer.

Works in any position (Versatile installation in the pipeline).

Dynamic quick closing of the disc reducing the velocity of flow return.

Few moving parts. Only disc is exposed to wear.

Axial movement of the disc: the internal shape provides a streamlined flow path

with venturi effect which results in low pressure drop.

Short stroke of the disc assisted by a spring allows quick response to

reverse flow velocity acceleration.

Different spring torques for different applications and critical velocities.

VALVES AXIAL – NOZZLE COMPARISON

SPECIAL ALLOYS

Over the years the most frequent used materials on the desalination market have been the so called “Superstainless” or “ superaustenitic”, which anti corrosive properties are superior to austenitic steels.

Due to the price increment on the prime materials and as an alternative more competitive for these materials, Duplex and Superduplex of second generation have been introduced in the market of desalination.

The family of Duplex and Super duplex Stainless steels offer a significant advantage over Standard austinic steels.

The 50/50 ferrite /austenite structure gives improved corrosion and abrasion resistance together with improved tensile and yield properties.

Duplex Composition range is obtained by a complex structure, and therefore requires a much greater degree of technology, melting and process control compared with austenitic stainless steel constructions.

CASTFLOW VALVES S.L. has been experiencing the production of check valves in Duplex stainless steel for the last years, increasing our knowledge on the complex casting technology.

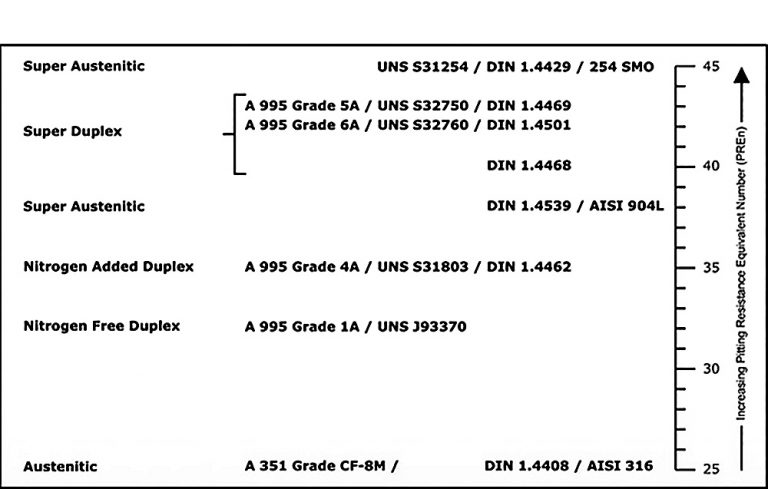

PITTING RESISTANCE EQUIVALENT NUMBER (PREN)

The resistance to pitting of an alloy is of vital importance , particularly so in handling seawater. Assessment of resistance to pitting is often made by use of a pitting resistance equivalent number which, when this takes account of Cr Mo and N is referred to as a PREn Number.

Calculation is made on the basis of the following.

PREN= %Cr+ 3.3%Mo16%N