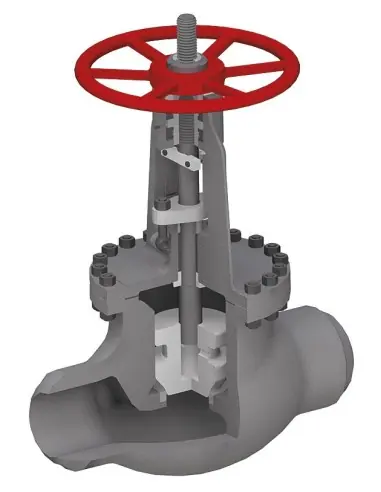

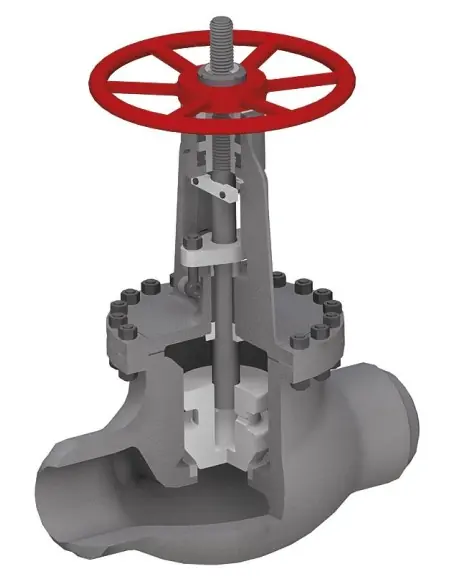

FLUITEK ORSENIGO VALVES has introduced a complete line of this type of product. Their function is to combine the off service by blocking the disc in the closed position, with a lift non return check valve service, when stem, not firmly connected with the disc, is in the up position. Construction is with straight pattern (also called “T-pattern”). Normal construction is with cast body and bonnet. Ends configuration is either with flanged ends or with butt weld ends. Materials range from carbon steel to low alloy steel, to austenitic stainless steel, to austenitic-ferritic stainless steels (duplex), to nickel alloys.

Materials are either to ASTM/ASME standards or to EN standards, either harmonized or calculated to design conditions. Pressure classes (per ANSI standard) are normally ranging from 150# to 300# to 600#.