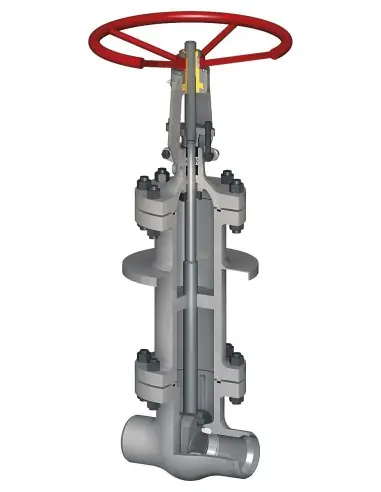

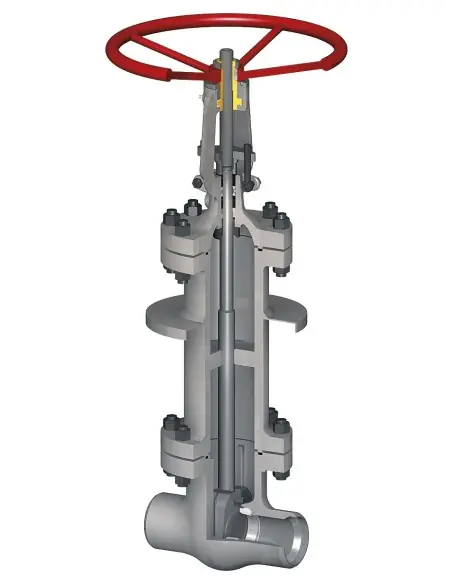

FLUITEK ORSENIGO VALVES provides considerable experience in the production of gate valves for low temperature service (below -50°C). Low temperature test in accordance with BS 6364:1984 Appendix A is available.

Standard materials are austenitic steels (e.g. CF8/CF3; CF8M/CF3M) with metal seals and /or soft inserts (usually based on PTFE). The implementation requires extremely accurate machining for a smooth functioning of the valve in service.

A special kind of service is the oxygen service in the air liquefaction plants. For that application FLUITEK ORSENIGO VALVES has developed a procedure and a dedicated production shop. The valves are cleaned and treated in order to meet the industry requirements, with the capability of performing quantitative verification of the degree of cleanliness.

The valves are supplied on request with mounting plate for installation in “cold box”.

Equalizing systems are provided to prevent trapping of fluid in the body and bonnet estension cavities.