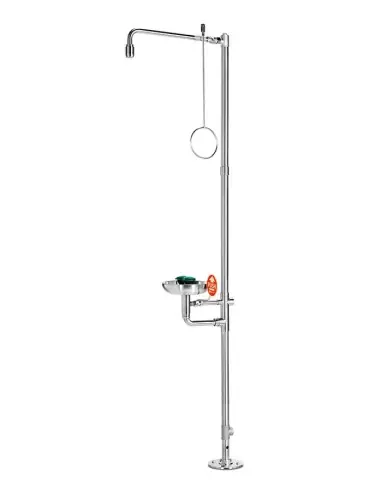

Industrial safety shower, freestanding, draining eye shower over stand pipe - PremiumLine - BR 837 595 | B-Safety

Features & Benefits of the Industrial safety shower, freestanding, draining eye shower over stand pipe - PremiumLine - BR 837 595 | B-Safety

Experience maximum safety and reliability with the Industrial safety shower, freestanding, draining eye shower over stand pipe - PremiumLine - BR 837 595 | B-Safety. Specially designed for demanding industrial environments, this advanced safety shower delivers instant protection in hazardous situations, ensuring your workplace meets strict safety requirements.

This premium freestanding unit responds quickly—just a pull of the lever releases a steady, full-body cascade of water, effectively flushing away contaminants. Integrated with a draining eye shower mounted above the stand pipe, it offers precise eye care while keeping the water fresh and hygienic. The large, intuitive push handle is easy to operate, even when time is short and stress is high.

Main Features

- Robust Construction: Made from high-grade, corrosion-resistant materials to withstand tough industrial use without compromising function or safety.

- Freestanding Flexibility: No wall mounting needed—position it exactly where immediate access is critical.

- Efficient Draining System: Eye shower drains automatically, preventing standing water and reducing risk of contamination.

- Simple Operation: Large and clearly marked operating handles make activation fast and hassle-free in an emergency.

- Visible Safety: Bold color and universal safety symbols ensure it’s easy to spot from a distance.

- Consistent Water Flow: Delivers powerful, even water coverage at a moment’s notice, offering vital first aid when needed.

Benefits

- Minimizes workplace injuries by providing immediate decontamination through effective whole-body and eye rinsing.

- Prevents complications from hazardous substance exposure by combining a full shower and eyewash in one station.

- Keeps water fresh and sanitary with its advanced draining mechanism.

- Highly durable for long-lasting use under demanding industrial conditions.

- Easy to install and maintain, ensuring continued protection for every employee.

Choose the Industrial safety shower, freestanding, draining eye shower over stand pipe - PremiumLine - BR 837 595 | B-Safety for practical, reliable, and instant safety—ensuring your team stays protected every day.

Description

Certification