Continuous Blowdown Valve | Gestra – Ultimate Efficiency for Industrial Boiler Houses

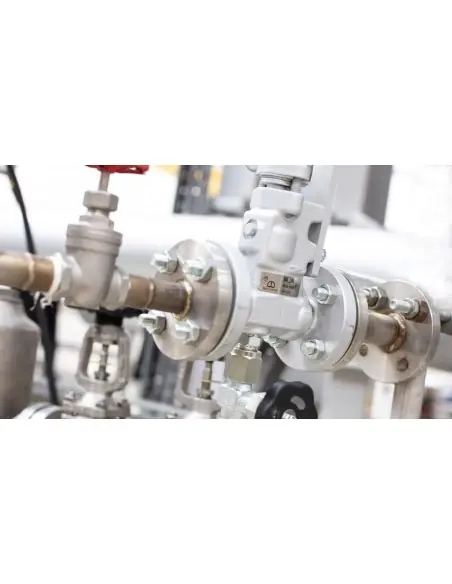

The Continuous Blowdown Valve | Gestra is a smart and reliable solution designed for modern industrial boiler houses. This precision-engineered valve ensures your boiler systems run cleanly, safely, and efficiently by automatically removing unwanted dissolved solids. With its robust construction and user-friendly operation, it stands out as a must-have for maintaining high-performance steam boilers.

Key Features and Benefits of Continuous Blowdown Valve | Gestra

- Maximum Boiler Protection: By constantly controlling the level of dissolved solids, the valve helps prevent dangerous build-up inside the boiler, keeping it in top working condition and avoiding costly damage.

- Efficient Water Use: The valve ensures only the right amount of water is released, reducing water waste and saving on energy and treatment costs.

- Easy Adjustment: Its simple setting mechanism allows for quick changes in blowdown rates, ensuring optimal performance and adapting to your boiler’s needs without complicated procedures.

- Durable Construction: Made with high-quality materials, the Continuous Blowdown Valve | Gestra is built to withstand the toughest industrial environments, providing long-lasting, maintenance-free operation.

- Safety First: Continuous blowdown reduces the risk of dangerous foam and water carryover, ensuring safer operation for both equipment and personnel.

What sets the Continuous Blowdown Valve | Gestra apart is its ability to keep your system stable, clean, and efficient without the need for constant manual adjustment. The advanced design precisely regulates blowdown, so you get the best balance between performance and resource savings. Installation is straightforward, making it easy to fit into existing boiler setups.

With a focus on energy savings, safety, and minimal maintenance, this valve is an investment in both productivity and peace of mind. Trust the Continuous Blowdown Valve | Gestra to deliver outstanding results and reliability in any industrial boiler house.