Back Pressure Regulator - UV 7.5 | Mankenberg: Precision Control for Reliable Industrial Processes

Experience next-level process stability with the Back Pressure Regulator - UV 7.5 | Mankenberg, designed to deliver consistent pressure management in a wide range of industrial applications. This advanced regulator ensures your system operates efficiently, safely, and with minimal downtime, making it an essential component for modern industrial setups.

Features & Benefits of the Back Pressure Regulator - UV 7.5 | Mankenberg

- Consistent Pressure Control: Enjoy stable back pressure, preventing system fluctuations and ensuring smooth operation even when demands change.

- Robust Construction: Made with high-quality, corrosion-resistant materials that guarantee a long service life in tough industrial environments.

- Maintenance-Friendly Design: The regulator is designed for easy installation and straightforward maintenance, reducing downtime and saving you money.

- Versatile Application: Ideal for liquids and gases, it adapts seamlessly to different industrial uses, from chemical processing to water treatment.

- Precision Engineering: Delivers accurate pressure regulation, enhancing overall process quality and protecting sensitive equipment from pressure spikes.

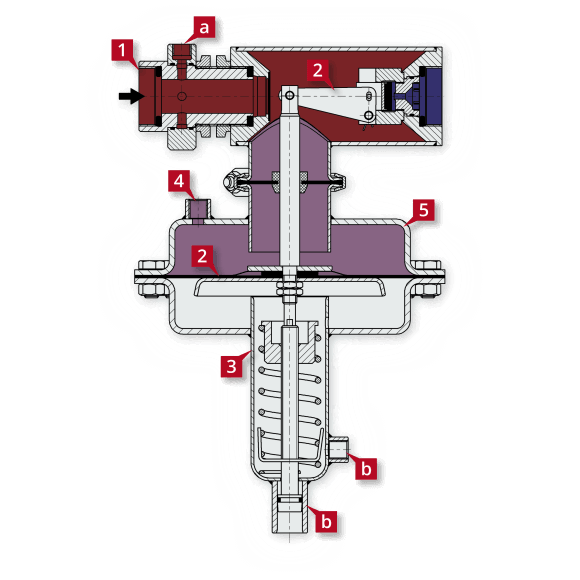

The Back Pressure Regulator - UV 7.5 | Mankenberg stands out for its advanced diaphragm technology, providing rapid response to pressure changes. Its user-friendly design makes operation simple, while its sturdy housing resists wear and tear over time. Thanks to its reliable sealing system, leaks are minimized, supporting both environmental safety and efficient production.

Upgrade your industrial process with a regulator that combines cutting-edge technology, ease of use, and dependable protection. The Back Pressure Regulator - UV 7.5 | Mankenberg is your solution for achieving precise and safe pressure control every day.