Unrivalled Flow Control: Discover the Pressure Reducing Valves - DM 618Z | Mankenberg

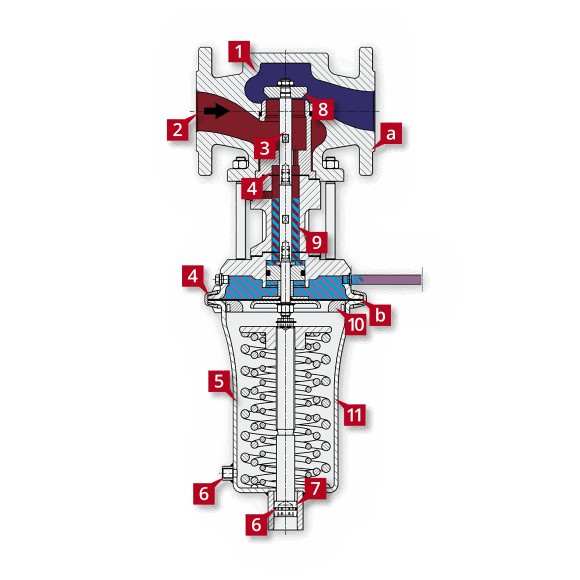

The Pressure Reducing Valves - DM 618Z | Mankenberg are designed to deliver precise pressure regulation in demanding industrial environments. Built for reliability and longevity, these valves ensure your systems run smoothly and efficiently, no matter the pressure fluctuations in your pipelines.

Features & Benefits of Pressure Reducing Valves - DM 618Z | Mankenberg

- Consistent Pressure Output: Maintain stable downstream pressure despite upstream changes. This prevents equipment stress and helps protect sensitive components.

- Rugged Stainless Steel Construction: Crafted from high-grade stainless steel, the DM 618Z stands up to tough industrial conditions—providing corrosion resistance and durability for years of trouble-free service.

- Easy Installation & Maintenance: Its compact design makes the valve simple to install, even in tight spaces. Routine checks and servicing are straightforward, minimizing downtime.

- Smooth Performance: The advanced valve mechanism guarantees smooth, vibration-free operation—reducing wear and extending the service life of connected equipment.

- Wide Pressure Range: The DM 618Z accommodates various industrial applications, from low to moderately high pressures, making it versatile for different processes.

- Precision Control: Fine-tune pressure settings for exact output—ideal for operations that require accuracy to ensure quality and safety.

Improve your process control by integrating the Pressure Reducing Valves - DM 618Z | Mankenberg into your setup. These valves offer dependable performance and help maintain optimal operating conditions, all while reducing maintenance needs and energy costs. Choose a valve trusted by industries worldwide for quality, innovation, and value.