Pressure Reducing Valves - DM 618 ASME | Mankenberg: Advanced Control for Reliable Industrial Performance

The Pressure Reducing Valves - DM 618 ASME | Mankenberg ensures reliable and consistent pressure management for a wide range of industrial processes. If you need a solution that delivers accuracy and durability, this valve stands out for its innovative design and top-tier performance.

Key Features & Benefits of Pressure Reducing Valves - DM 618 ASME | Mankenberg

- Consistent Pressure Regulation: This valve maintains stable outlet pressure, even when the incoming pressure fluctuates. It helps protect your equipment and processes from unexpected pressure surges, preventing costly downtime.

- Rugged Construction: Manufactured from high-quality stainless steel, the DM 618 ASME is built to last, even in tough industrial environments. Its robust design guarantees a long service life with minimal maintenance.

- Easy Integration: The standardized ASME flange connections make installation simple, ensuring compatibility with a wide range of piping systems. Save valuable time during setup and replacement operations.

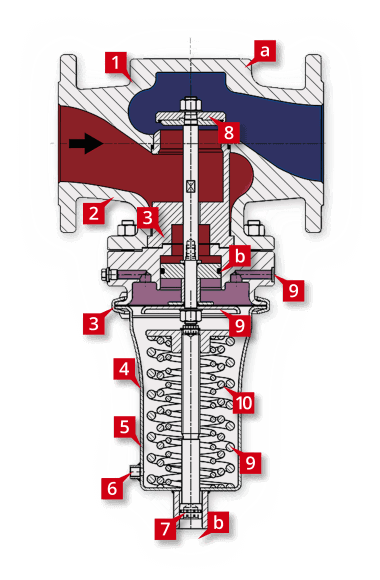

- Precision Engineering: Advanced internal components provide smooth and accurate pressure reduction. This not only enhances safety but also improves the efficiency and lifespan of downstream machinery.

- Low Maintenance: Thoughtfully designed for easy servicing, this valve reduces maintenance effort and keeps operational costs low. All functional parts are easily accessible for quick inspections and replacements.

- Versatility: Suitable for gases, steam, and liquids, the DM 618 ASME is highly adaptable and covers a broad range of applications, from chemical plants to power stations and beyond.

With the Pressure Reducing Valves - DM 618 ASME | Mankenberg, you receive a smart pressure control solution that meets the demanding needs of industrial operations. Its advanced technology means you get peace of mind, knowing your systems are operating safely and efficiently. Whether installing new lines or upgrading existing ones, this valve is a dependable choice for long-term performance and reliability.