Discover Reliability & Control: Pressure reducing valves - DM 618Z ASME | Mankenberg

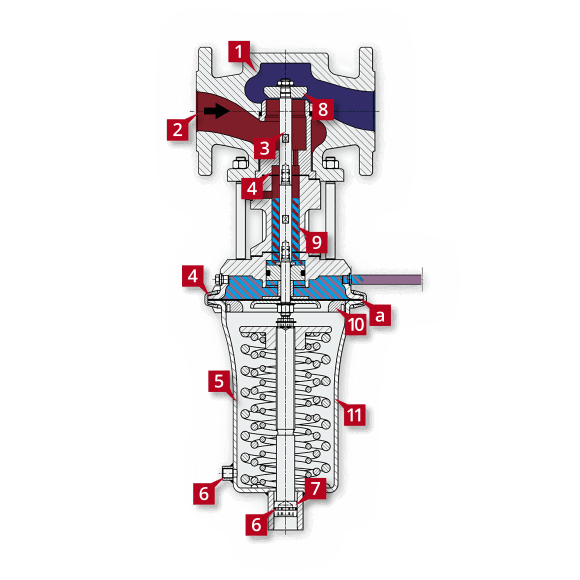

The Pressure reducing valves - DM 618Z ASME | Mankenberg are expertly engineered for efficient pressure regulation in industrial environments. Built to the highest ASME standards, these valves guarantee consistent performance and safe operations, regardless of system demands.

Features & Benefits: Pressure reducing valves - DM 618Z ASME | Mankenberg

- Precise Pressure Control: The DM 618Z ASME valve maintains consistent downstream pressure, preventing system overload or fluctuations. This leads to a safer and more reliable operation in your facility.

- Robust Construction: Made of high-quality materials, the valve stands up to demanding environments. It offers long service life and reduced maintenance needs, saving both time and money.

- Easy Integration: Designed for seamless installation, the DM 618Z ASME fits effortlessly into your existing piping systems. Its flexible connection options simplify setup in new or retrofit projects.

- Low Noise and Vibration: Advanced engineering ensures quiet operation, even under high flow conditions. Comfortable and stable workplace environments are now easier to maintain.

- Reliable Performance: The self-acting mechanism reacts instantly to pressure changes, delivering smooth and automatic adjustments without external energy or complicated controls.

- ASME Certified Safety: Compliant with strict ASME guidelines, these valves promote safety and operational peace of mind, meeting regulatory requirements in industrial applications across the globe.

With the Pressure reducing valves - DM 618Z ASME | Mankenberg, you gain powerful protection for sensitive equipment and processes. These valves support uninterrupted productivity by preventing unwanted pressure surges and ensuring optimal system conditions. Built to last and simple to operate, they offer a cost-effective solution that enhances your infrastructure’s safety, stability, and efficiency every day.