Bleeding & Venting Valve Type EB 1.32 | Mankenberg: Precision and Reliability for Every System

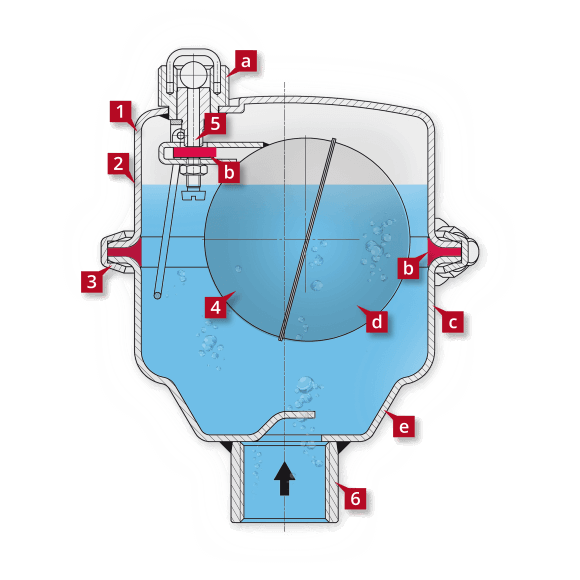

The Bleeding & Venting Valve Type EB 1.32 | Mankenberg is your dependable solution for efficient air release and safe venting in pipelines and tanks. This valve is engineered to deliver consistent performance, making your fluid systems run smoother and reducing the risk of air-related issues. With its intelligent design, it adds real value to any application—whether you are dealing with water, chemicals, or industrial fluids.

Features & Benefits of Bleeding & Venting Valve Type EB 1.32 | Mankenberg

- Automatic Air Removal: Ensures that trapped air escapes quickly, preventing interruptions and costly downtimes.

- Reliable Venting Action: Maintains system safety by releasing unwanted gases, which helps protect equipment from damage and extends its life.

- Robust Construction: Built with high-quality, corrosion-resistant materials for excellent durability, even in demanding environments.

- Compact Design: Easy to install, even in tight spaces, without sacrificing any performance.

- Easy Maintenance: Simplified structure means fewer parts, making servicing straightforward and minimizing maintenance time.

- Versatile Use: Suitable for a wide range of applications such as water treatment, chemical processing, heating systems, and more.

- Safe Operation: Prevents dangerous pressure build-ups by allowing gases to exit safely and efficiently.

The Bleeding & Venting Valve Type EB 1.32 | Mankenberg stands out for its smart, automatic functions that require minimal intervention. It’s designed to react instantly when air or gas builds up, making sure your system stays efficient and trouble-free. The mechanism is both sensitive and robust, ensuring dependable action regardless of the pressure or flow conditions.

Thanks to its sturdy materials, the valve resists harsh chemicals and aggressive fluids, making it a trustworthy part of any installation. Its compact size also means you can retrofit it into existing systems without any hassle. Maintenance is effortless; the valve’s construction allows for quick checks and cleaning, saving both time and effort.

From the first use, you’ll notice smoother system operation and less risk of breakdowns or pressure issues. By automatically handling venting, the Bleeding & Venting Valve Type EB 1.32 | Mankenberg protects your investment and ensures peace of mind—no special training required. It’s the perfect choice for anyone looking to boost reliability and safety in their pipeline or tank setup.