Unlock Precision and Safety: Bleeding & Venting Valve Type EB 1.12 | Mankenberg

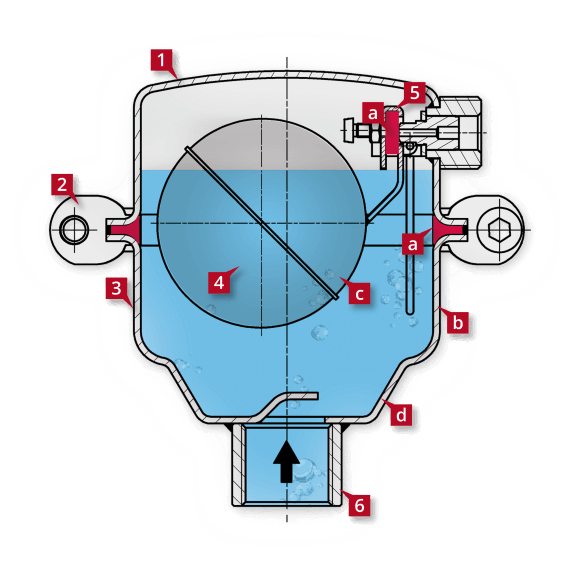

When it comes to maintaining the safest and most efficient industrial systems, the Bleeding & Venting Valve Type EB 1.12 | Mankenberg stands out as a smart, reliable choice. This advanced valve is designed to automatically remove unwanted air or gas from pipelines, tanks, and process equipment, ensuring your system runs at peak performance. With its robust build and intelligent features, it offers both protection and peace of mind, making it an essential addition to any setup.

Features & Benefits of the Bleeding & Venting Valve Type EB 1.12 | Mankenberg

- Automatic Air Release: The valve opens only when air or gas needs to be vented, providing worry-free operation and eliminating the risk of air pockets that can disrupt flow or damage equipment.

- Corrosion-Resistant Materials: Constructed from high-grade stainless steel, this valve resists wear and tear, even in challenging environments. It ensures durability and long service life, reducing maintenance costs over time.

- Leak-Proof Design: The precisely engineered sealing system prevents leaks, protecting your workspace and equipment from potential damage or contamination.

- Easy Installation: Its compact and lightweight design means it can be quickly and easily fitted into new or existing systems, minimizing downtime and hassle.

- Low Maintenance: Thanks to its self-cleaning mechanism and rugged construction, the valve rarely needs attention—saving you valuable time and resources.

- Versatile Applications: Suitable for a wide range of industries, from water treatment to food processing, the EB 1.12 adapts easily to your needs.

Using the Bleeding & Venting Valve Type EB 1.12 | Mankenberg ensures that unwanted air is quickly and safely expelled from your system. This not only prevents annoying noises and vibration but also protects sensitive pumps and instruments from malfunction. Built to handle demanding conditions, it promises reliability when you need it most. Whether you’re upgrading an existing line or building from scratch, this valve delivers efficiency, safety, and simplicity in one package.