Pressure reducing valves - DM 512 | Mankenberg: Reliable Pressure Control for Every Industrial Setting

Introducing the Pressure reducing valves - DM 512 | Mankenberg, your trusted solution for maintaining precise and safe pressure control in industrial applications. Engineered to deliver consistent results, this valve ensures your equipment operates smoothly and efficiently, reducing maintenance needs and prolonging the lifespan of your machinery.

Features and Benefits of Pressure reducing valves - DM 512 | Mankenberg

- Precise Pressure Regulation

Enjoy stable and accurate pressure management, which helps protect sensitive equipment and processes from fluctuations. The DM 512 keeps pressure exactly where you need it, every time. - Durable Construction

Built from robust stainless steel, the valve is corrosion-resistant and designed to perform even in tough industrial environments. Its sturdy build lowers the risk of breakdowns and ensures long service life. - Low Maintenance Design

The DM 512 requires minimal upkeep, helping you avoid costly downtime and frequent repairs. Cleaning and servicing are straightforward, so your operations stay productive. - Versatile Applications

Ideal for a variety of industries including chemical, pharmaceutical, and food processing. Its reliable performance makes it suitable for handling gases, steam, and liquids with ease. - Fast and Simple Installation

The compact and user-friendly DM 512 is easy to fit into existing systems, saving time during setup and reducing installation costs. - Energy Efficient

By keeping pressure steady, the DM 512 reduces unnecessary energy consumption and helps you operate more sustainably.

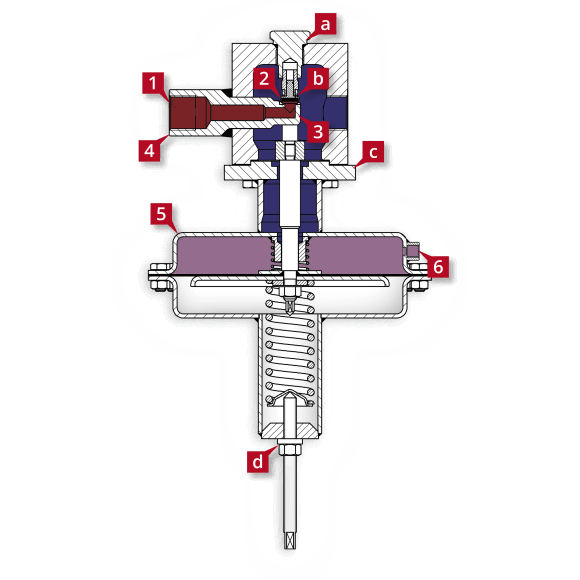

The Pressure reducing valves - DM 512 | Mankenberg stands out for its dependable performance and innovative design. Its spring-loaded mechanism reacts instantly to pressure changes, ensuring your systems stay balanced and protected at all times. With an excellent sealing system, it eliminates leaks and delivers reliable results day after day.

Whether you need to manage steam in a heating plant or ensure safe water flow in a manufacturing line, the DM 512 provides peace of mind and superior control. Choose this valve for safety, reliability, and efficiency across all your industrial processes.