Precision Meets Reliability: Pressure Reducing Valves - DM 510/514 | Mankenberg

Experience unmatched control and safety in your industrial processes with the Pressure Reducing Valves - DM 510/514 | Mankenberg. Built for demanding environments, these valves ensure stable and precise pressure management, safeguarding your equipment and optimizing efficiency without manual intervention. Made by Mankenberg, a trusted leader in valve technology, the DM 510/514 series is designed to keep your systems running smoothly, no matter the challenge.

Features and Benefits of Pressure Reducing Valves - DM 510/514 | Mankenberg

- Automatic Pressure Control: Maintains optimal downstream pressure, ensuring constant system performance and reducing the need for continual system checks.

- Robust Construction: Engineered with high-quality stainless steel for maximum durability and corrosion resistance, ideal for tough industrial settings.

- Wide Application Range: Suitable for various mediums, including gases, steam, and liquids, making them versatile for multiple industrial uses.

- Easy Installation & Maintenance: Compact design allows for seamless integration into existing pipelines, with minimal maintenance requirements to keep operations hassle-free.

- Energy Savings: By preventing unnecessary overpressure, the DM 510/514 valves help conserve energy, contributing directly to cost efficiency in your operations.

- Reliable Safety: Protects downstream equipment from pressure spikes, reducing the risk of breakdowns and costly repairs.

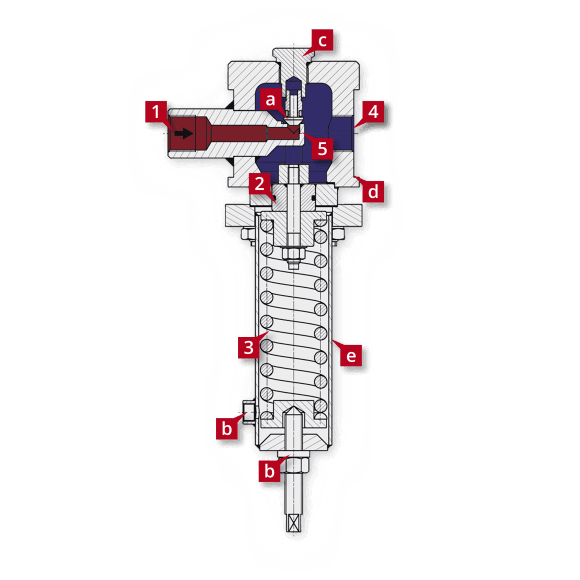

- Precise Regulation: Advanced internal mechanisms guarantee steady pressure output, even during demand fluctuations, making your process more predictable and safer.

Take control of your industrial processes with the Pressure Reducing Valves - DM 510/514 | Mankenberg. With their easy-to-understand operation and minimal maintenance, they are perfect for busy facilities seeking effective solutions without the hassle. Minimize downtime, extend equipment life, and keep your production line running as efficiently as possible.

Trust in the engineering excellence of Mankenberg and experience the benefits of reliable pressure regulation tailored for your industry’s needs.