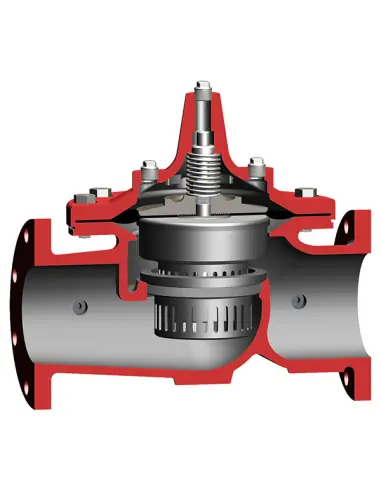

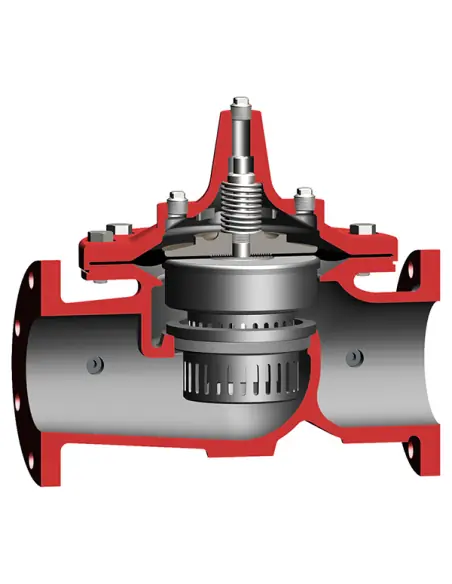

Cla-Val’s KO Anti-Cavitation Trim represents a dramatic departure from the standard approaches usually employed to fight cavitation in valves that are required to undergo extreme pressure differentials and high-velocity flow conditions.

Constructed of 316 stainless steel, the seat and disc guide feature dual interlocked sleeves containing cast radial slots that deflect internal flow to impinge upon itself, harmlessly dissipating potential noise and cavitation damage. The cast radial slots create a larger flow path than is possible with the standard drilled holes typically employed by other anti-cavitation valves currently available in the marketplace. The uniquely designed radial slots in the seat and disc guides also lessen the possibility of fouling if small particles are present in the water.

The Anti-Cavitation Trim components can be retrofitted to existing valves if the application indicates an appropriate need.

Typical Applications:

- Pressure reducing valve stations

- Tank fill valve applications

- Noise reduction in high-rise building valve stations

- Reservoir level control valve applications

- Booster pump bypass stations

- Offshore fire pump relief valve protection

- Applications with discharge to atmosphere

- Any application where valves are subjected to extreme pressure differentials or high velocity flow conditions