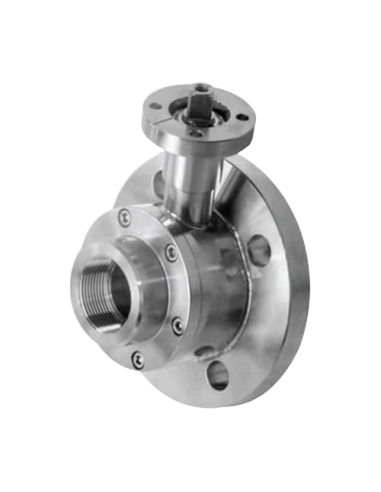

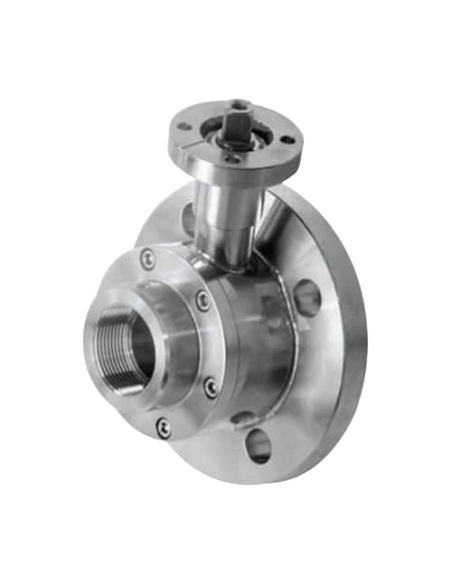

TWO-way ball valve STEM BENT BOTTOM with “INTEGRAL SEAL”

Use: Valve for tank bottom

Antistatic device ATEX:

II 2G Ex h IIC T4 Gb

II 2D Ex h IIIC T135°C Db

Drive: ISO 5211 – DIN 3337 flange for actuator

Connections: Tank side flange fixed UNI EN 1092 and ISO 228 Female on output side

Flow: Full

Material: Aisi 316L (1.4404)

Measure: from DN40 to DN125

Seals: Virgin P.T.F.E.

Operating temperature: -20°C+160°C

Outer finish: Polished

Screws for mounting actuator included

On request:

M.O.C.A. CE 1935/2004

• MANUAL with LEVER Kit

• Counterflanges for Tank