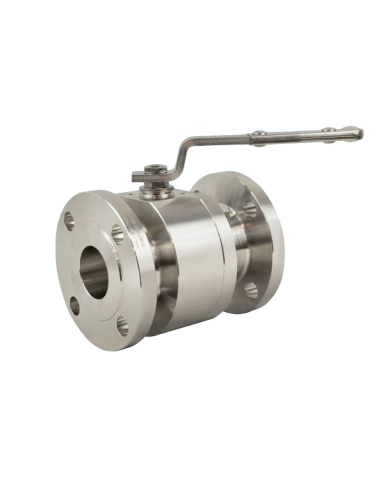

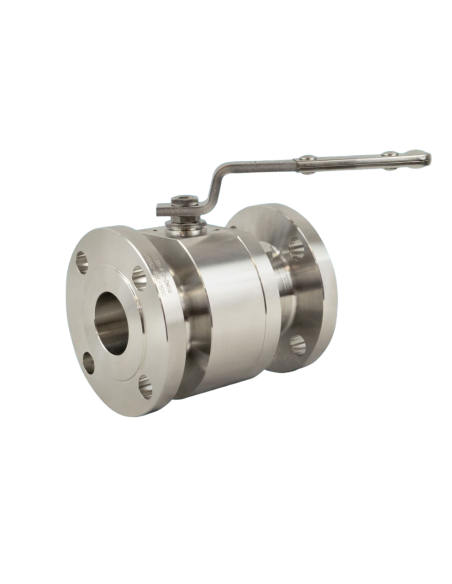

Ball valve 2 piece SPLIT BODY type full bore ISO 14313, manufactured from round bar or casting, construction according to EN 12516.2; ASME B16.34; EN 1759-1 ; ASME B16.5; ISO 14313; ANSI B16.10; EN 558 (Basic series 3).

Available size from DN 15 to DN 200 in carbon steel, stainless steel and special steel

Rating ANSI 150 (on request PN 16).

Double seals on body/end junction (patent n°00216919)

Chevron ring on stem.

On request:

– with o’ring on stem (patent n°00219688).

– fire-safe execution according to ISO 10497 API 607

– fire-safe execution according to BS6755 API 607/6FA (patent n° 00219617).

– cryogenic execution ISO 28921

– according to PED 14/68/UE directive

– according to TPED 2010/35/UE directive

– according to ATEX 14/34/UE directive

– degreased according to ISO 23208 for oxigen service

– certified in safety system S.I.L. 3.

– certified for fugitive emission in class “A” ISO 15848.

Standard productions

anti blow out proof stem

construction and marking BS 5351

carbon steel valves painted with first coat of epoxy-

polyammidic RAL 5012 35 microns

antistatic device

top flange ISO 5211

all valves 100% air tested under water at 100 psi

On demand accessories

PTFE / glass renforced PTFE half shell

PTFE seats filled glass – carbon – S.S. – bronze, metal core

stem extension

cryogenic extension

oval handle

pneumatic actuator double/single acting

electric actuator

manual gear box

pneumatic / electro-pneumatic positioner