Discover the Advanced Features of the Wastewater Air Valve Type SCF-RFP | CSA

Are you looking for a high-quality wastewater air valve that offers superior performance and durability? Look no further than the Wastewater Air Valve Type SCF-RFP | CSA. This innovative product is designed to efficiently release air and gases from wastewater systems, ensuring optimal functionality and preventing potential issues.

Here are some of the key benefits of the Wastewater Air Valve Type SCF-RFP | CSA:

- Efficient Air Release: The valve is specifically designed to effectively release air and gases from wastewater systems, preventing air locking and ensuring smooth operation.

- Durable Construction: Made from high-quality materials, this valve is built to last and withstand the demands of wastewater applications, ensuring long-term performance.

- Corrosion Resistance: The valve is resistant to corrosion, making it ideal for use in harsh wastewater environments where corrosion can be a common issue.

- Easy Installation: With its user-friendly design, the valve is easy to install and integrate into existing wastewater systems, saving you time and effort.

- Reliable Performance: The Wastewater Air Valve Type SCF-RFP | CSA is designed for reliable performance, ensuring consistent air release and uninterrupted operation of your wastewater system.

Additionally, the Wastewater Air Valve Type SCF-RFP | CSA features advanced technology and innovative design elements that set it apart from traditional air valves. Here are some of its advanced features:

- Float Mechanism: The valve is equipped with a float mechanism that automatically adjusts the air release rate based on the system's needs, ensuring efficient operation.

- Pressure Relief Function: In case of excessive pressure buildup in the system, the valve has a pressure relief function that helps maintain optimal pressure levels and prevent damage.

- Easy Maintenance: The valve is designed for easy maintenance, with accessible components that can be quickly inspected and serviced, minimizing downtime.

- Compact Design: The compact design of the valve allows for easy installation in tight spaces, making it suitable for a variety of wastewater system configurations.

- Compliance: The Wastewater Air Valve Type SCF-RFP | CSA meets high standards of quality and safety, ensuring compliance with industry regulations and requirements.

Whether you are upgrading an existing wastewater system or installing a new one, the Wastewater Air Valve Type SCF-RFP | CSA is the perfect choice for reliable air release and optimal system performance. Invest in this advanced valve today and experience the difference it can make in your wastewater operations.

Description

Certifications

Quality e certifications

Quality in its entirety is now an essential requirement for all businesses that aim at gaining and maintaining their position in today's market.

For this reason we have always had the objective of guaranteeing a product managing cycle which, developing a synergy between the various sectors of the company ensures:

- Quick and precise information.

- Evaluation of data received and immediate responses.

- Rigorous control of incoming and outgoing products.

The production cycle, targets a constant improvement of our products, aims at complete customer satisfaction ensures predetermined margins of tolerance establishing production standards so as to guarantee that the semi-finished products reach the next production stage with the required specifications.

All our valves are made of ductile cast iron GJS 450-10 and in absolute compliance with Italian and European standards and are designed to work at a pressure of 25-40 bars. The work is carried out only by means of numerically controlled lathes, mills, horizontal machining units and subsequently examined step-by-step following strict procedures. Internal components of our valves are largely made of stainless steel or other high resistant materials for the maximum prevention of cavitation effects and corrosion.

Painting, pre-treated by sand-blasting grade SA 2,5, is carried out inside a fluidized bed containing epoxy powder, which guarantees maximum surface protection.

All our products are tested under water pressure and certified.

Company policy

CSA deals with the design and production of material for pressure systems for aqueduct, sewage and industrial use and the marketing of all types of valves and solutions for the regulation of pressure systems in the aqueduct, sewerage and industrial sectors.

Mission

Its corporate mission is to be recognized as a structured and leading company for the production of pressure systems for aqueduct, sewage and industrial use.

Our target market consists of around 65% of foreign customers and the remaining 35% of customers in the Italian territory.

The Quality Management System of CSA s.r.l. must guarantee:

- customer satisfaction through the creation of products according to the required standards and specifications

- continuous improvement of the effectiveness / efficiency of all the company processes.

For this reason the management of the company together with all the company resources is committed to the continuous improvement of the performance of the company and therefore aimed at managerial, technical and professional growth.

The principles and methodologies of Quality have therefore been an inspiring model in the management and management of the activities of the company, which is constantly engaged in the analysis of the Customer's expectations, to guarantee your maximum satisfaction.

The Quality System is implemented through processes that take place within the company with the collaboration of individual functions and all employees.

Our strengths are:

- Technical development of new products suitable for particular applications also at the request of the customer, in addition to a range of standard products on the price list. The development is carried out by our internal Technical Department with attention aimed at complying with sector regulations and national standards;

- Assistance to the customer in all phases of order acquisition, order fulfilment and post delivery assistance thanks to commercial and operational personnel able to intervene to solve problems;

- Product quality: we guarantee the quality of our products thanks to a careful control of raw materials and selection of qualified suppliers and to the verification of 100% of the products;

- Training and periodic training of our staff;

- Periodic preventive maintenance of the equipment and calibration of the measuring instruments.

Company Strategies

The company sets the following business strategies for achieving its objectives:

- Establish contracts with new retailers worldwide to increase the number of customers also in terms of turnover;

- Development of post-sales assistance service both by telephone and through on-site assistance;

- Strengthening contacts with the customer through commercial contacts and direct meetings;

- Careful selection of suppliers through checks on the same and control of the material in acceptance;

- Warehouse management and production planning in order to meet customer delivery times;

- Development of new products and obtaining approvals for the marketing of products suitable for contact with water intended for human consumption.

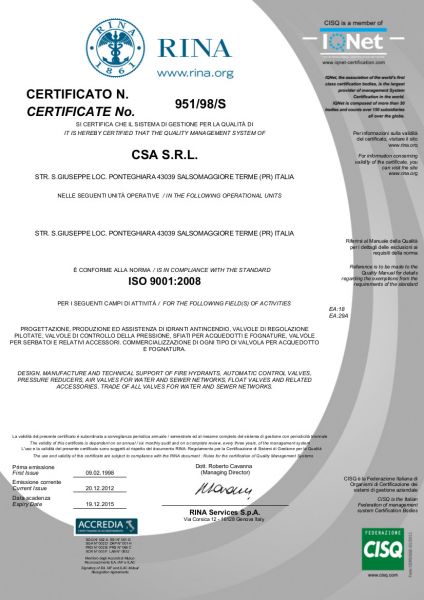

ISO certificates

Since 1998 all procedures, without exclusion, are certified according to the regulation ISO 9001:2008 by RINA, Registro Italiano Navale.

Standards applied

Quality management

UNI EN ISO 9000:2005

Quality management system - Fundamentals and vocabulary

UNI EN ISO 9001:2015

Quality management system - Requirements

General standards

UNI EN 1563:2012

Founding - Spheroidal graphite cast irons.

UNI EN 545:2010

Ductile iron pipes, fittings, accessories and their joints for water pipelines - Requirements and test methods

UNI 8574-6:1984

Painted products. Test methods. Surface adherence.

UNI EN ISO 2178:1998

Non-magnetic coatings on magnetic substrates - Measurement of coating thickness - Magnetic method

UNI EN 1092-2:1999

Flanges and their joints - Circular flanges for pipes, valves, fittings and accessories, PN designated - Part 2: Cast iron flanges

Valves

UNI EN 558:2012

Industrial valves - Face-to-face and centre-to-face dimensions of metal valves for use in flanged pipe systems - PN and Class designated valves

UNI EN 1074 -1:2001

Valves for water supply - Fitness for purpose requirements and appropriate verification tests - Part 1: General requirements

UNI EN 12266-1:2012

Industrial valves - Testing of metallic valves - Part 1: Pressure tests, test procedures and acceptance criteria - Mandatory requirements

Air valves

UNI EN 1074-4:2002

Valves for water supply - Fitness for purpose requirements and appropriate verification tests - Part 4: Air valves

Control valves

UNI EN 1074-5:2002

Valves for water supply - Fitness for purpose requirements and appropriate verification tests - Part 5: Control valves