Seat design

- Double piston effect downstream & upstream-DIB I

- Double piston effect downstream & single piston effect upstream-DIB II

- Seat sealing injector

Stem

- Stem sealing injector

- Stem or bonnet extension

- Design according to fugitive emissions

- Locking device

Others

- Overlay on seat area or on all wetted parts

- Heating or cooling jacket

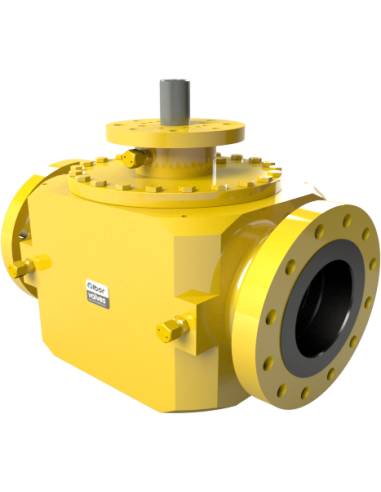

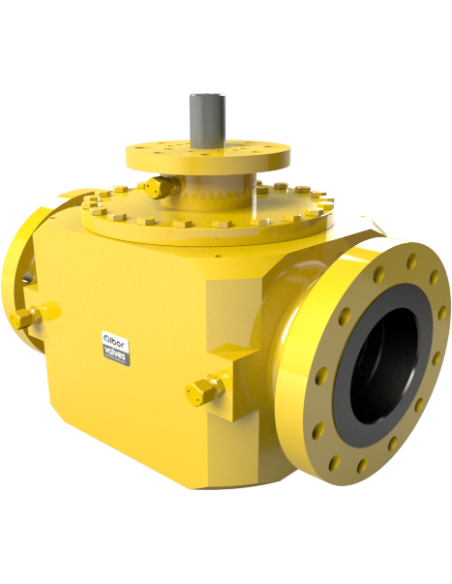

Connections

Flanged End: ASME B16.5 / GOST 12815-80 / EN 1092.1

Socket Weld End: ASME B16.11

**integral nipples and available

Butt Weld End: ASME B16.25

**integral nipples and available

Threaded NPT End: ASME B1.20.1

Threaded BSPP OR BSPT: BS21

Others