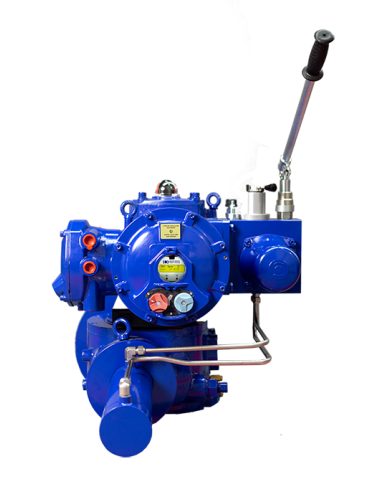

PRODUCT SPECIFICATIONS

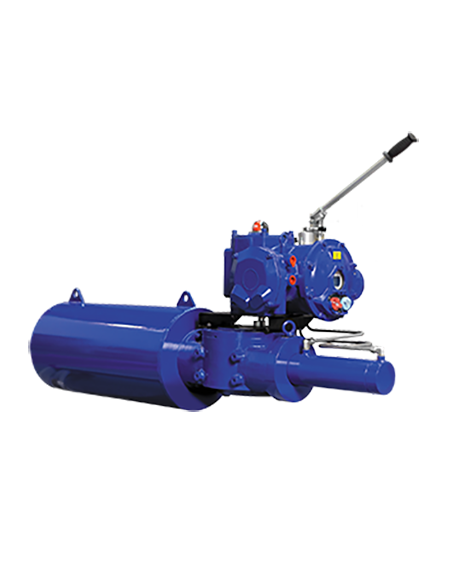

TORQUE RANGE:

- From 25 to 700 000 Nm for rotary and from 1.2 to 8 000 kN force for linear actuator

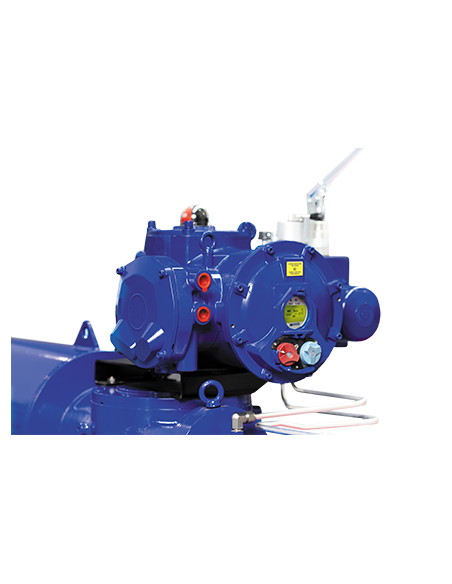

INTEGRATED CONTROL

BC DUTY & MODULATING CLASSIFICATION

- On-Off: Class A

- Inching / Positioning

- Modulating/Régulation: Class III

ENVIRONMENT: IP 67 / C5 / T: -20°C ...+60°C (+70°C AS AN OPTION)

EXPLOSION PROOF (ATEX, IEC EX)

PRODUCT BENEFITS

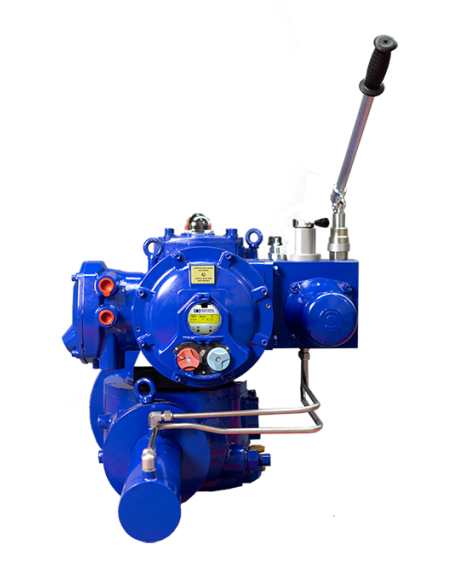

SECURITY AT ALL LEVELS & EASY MAINTENANCE

- Protect your installation and maximize site protection, thanks to BERNARD CONTROLS actuators’ smart functions.

- In case of power failure to the solenoid, the spring will drive the FSE and valve to the safety position. When the power supply is restored (no resetting of the spring is required), the actuator is immediately available for normal operation.

- Partial stroking : check the availability of the connected MOVs by executing of a very short return travel, and get a warning if problems occurs.

- Easy to install : the FSE is self contained, it only requires electrical power.

- Reduced maintenance : actuators are lubricated for the product lifetime and do not require any periodic maintenance.

- Extending life time of the valve : no "Hard Closing", slamming the Valve into the seat.

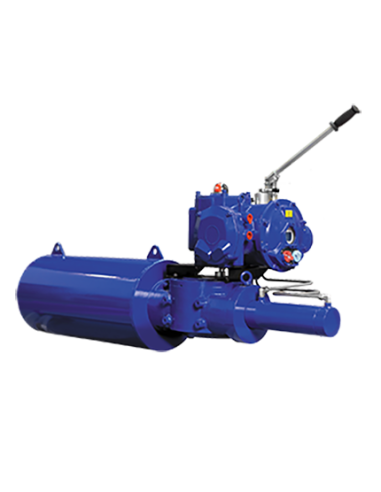

UNIQUE DESIGN & ENHANCED PERFORMANCES

- IP67, double-sealing protection, coating C5-M as standard

- Adress all type of applications: wide torque range from 25Nm to 700 000Nm for rotary and from 1.2 up to 8 000 kN force for linear actuator.

- Compact and optimized design : no need for air compressors, filtration, and dryer.

- Easy control system: all components are integrated into the manifold.

- Reduced risks of leakage thanks to considerably minimized circuitry.

- Very precise hydraulic control

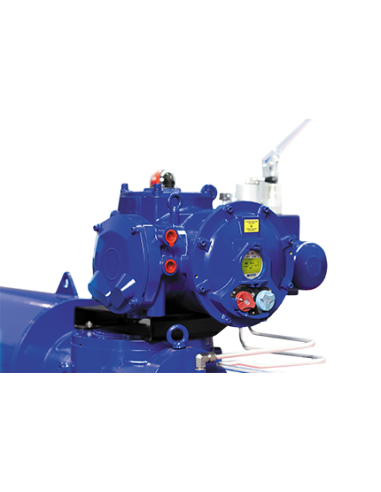

USER-FRIENDLY & INTUITIVE CONTROLS

- Non intrusive settings thanks to the integrated control.

- LCD display gives a clear status of the actuator and of the control system. Menu guided settings using clear messages, without abbreviations.

- 2 LEDs (red/green, freely assigned) indicate the position (close/open) at ends of travel, and direction of running (blinking).

- Local commands with two selectors, which can be inhibited remotely if needed.

- Advanced monitoring and diagnostic functions of the integrated control: Emergency Shutdown (ESD), Partial Stroke Test (PST), timer, alarm customization, operation monitoring…