Industrial safety shower, freestanding, with eye shower with stainless steel bowl - PremiumLine - BR 837 095 | B-Safety

Industrial safety shower, freestanding, with eye shower with stainless steel bowl - PremiumLine - BR 837 095 | B-Safety: Features and Benefits

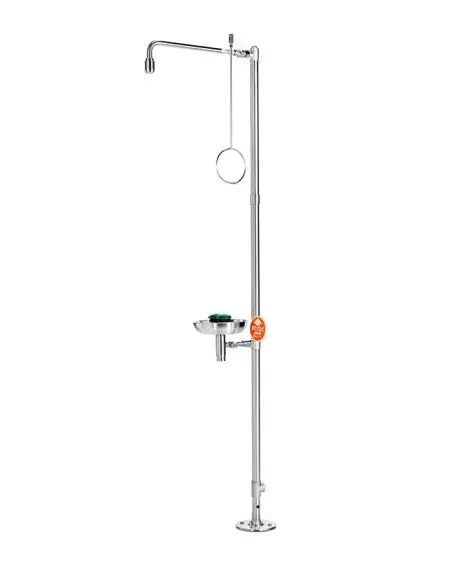

The Industrial safety shower, freestanding, with eye shower with stainless steel bowl - PremiumLine - BR 837 095 | B-Safety is your trusted partner in workplace safety. Specially designed for demanding industrial environments, this robust solution delivers rapid and effective emergency response when every second counts. Its thoughtful construction ensures that both full-body and eye rinsing are immediately accessible, providing essential protection in hazardous situations.

- All-in-one Protection: This unit combines a powerful body shower with a precision eye wash station. The stainless steel bowl ensures durability and hygiene, offering a reliable rinse in case of contact with harmful substances.

- Freestanding Convenience: With its self-supporting design, you can place the shower exactly where it’s needed most. No complicated installation—just simple, sturdy safety you can count on.

- Immediate Activation: Easy-to-use pull-rod and push-lever controls allow for instant water flow, enabling quick response to accidents or chemical splashes.

- Premium Materials: Built with corrosion-resistant stainless steel, the unit is made to withstand tough industrial conditions and frequent use without compromise.

- Enhanced Visibility: High-visibility markings make it easy to locate in an emergency, even under stress or in low-light environments.

- User-friendly Safety: Clear instructions and ergonomic operation mean anyone can activate the shower or eye wash, making it ideal for facilities with diverse teams.

Investing in the Industrial safety shower, freestanding, with eye shower with stainless steel bowl - PremiumLine - BR 837 095 | B-Safety means peace of mind for every shift. It’s a straightforward way to reinforce your safety standards and demonstrate care for your team. This product represents the perfect balance of technology and practicality, offering efficient emergency decontamination with minimal maintenance. Install it in your facility and be prepared for unexpected incidents—because safety should never be left to chance.

Description

Certification